|

Operating Screen — A complete overview

of all experimental parameters:

Choice of

Detectors

The AMI-200 comes standard with a thermal conductivity detector. An

integrated mass spectrometer and a flame ionization detector are also

available. Any other detector that provides ananalog ouput or can communicate

with a PC can be integrated.

Gas Blending

Capabilities

The AMI-200 comes standard with gas blending capabilities, obviating any need

to purchase expensive gas blends to conduct experiments such as TPR or TPO.

The AMI-200 includes an auxiliary gas line by means of which a third gas can

be mixed with the carrier gas to provide custom-blended gases. A low volume,

in-line static gas mixer assures homogeneity of the resulting blend. The gas

blending capability also facilitates the use of the AMI-200 as a gas-phase,

atmospheric reactor.

Our Expertise

Altamira was founded by catalyst researchers. We understand your

requirements. Our experts are available to answer your questions and help in

your applications.

We will be happy to customize a system to meet your exact needs. Some

customizations which we have undertaken include: a separate pre-treatment

station controlled by the computer; addition of liquid feeds for use of the

instrument as a reactor; incorporation of methanizer to a flame ionization

detector; design of a system dedicated to oxygen storage capacity (OSC);

modification to permit fast changes in feed composition, as fast as 1 Hz, for

aging studies.

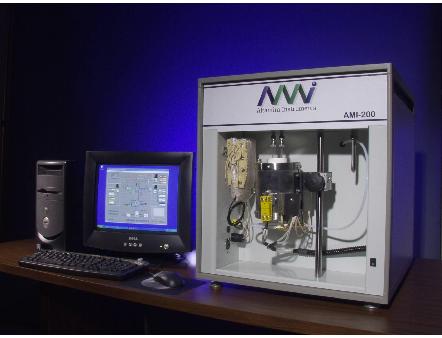

Specifications:

• Catalyst Charge: 0.1 – 1.0 grams

• Temperature Range: -100°C to +1200°C with Subambient Option

• 30°C/minute standard (Other Ramp Rates Available)

• Operating Pressure: Atmospheric

• Gases: 4 carrier, 4 treatment, 2 auxiliary (Others Available)

• Gas Flow Rates: 5 to 50 sccm (Others Available)

• Reactor Types: Quartz U-tubes, Bubble Tubes, Monolith Tubes (up to

1" diameter)

• Primary Detectors: 4 filament TCD with choice of material (W, Au/W)

• Materials of Construction: Flow path: 316 stainless steel

• Seals: Viton, Buna-N, or Premium Seals (depending on customer

chemical compatibility requirements)

• Dimensions: 56 cm (W). 60 cm (H), 61 cm (D)

• Weight: approximately 55 kg (120 lbs)

• Power Requirements: 110-120 or 220-240 Volts, single phase, 50 or 60

Hz. 15 amp service

• Computer Specifications: Pentium IV processor, 1.2 GHz (minimum), 256

MB RAM, 30 GB Hard Drive Windows XP

AMI-200 Features

Seven (7) Standard Procedures - Pulse chemisorption, TPR/TPO, TPD,

TPRx, treatment, pulse calibration, and flow BET.

Ability to link 99 procedures into one experiment.

Three Independent Gas Sources - In addition to a carrier gas and a

treatment gas, the AMI-200 provides one additional

independently controlled auxiliary gas inlet which can be blended with the

carrier gas.

Ten (10) Gas Ports - Gas ports located on the back of the instrument

minimizes the time expended changing gases. Four ports

each for treatment and carrier gases. Two ports are available for gas

blending or auxiliary gases. Additional ports can be added.

Electronic Flow Controllers - Unit uses high quality linear mass flow

controllers to display and control gas flows. Flow rate span is 0-50 Sccm

(standard). Other ranges are available upon request.

Interchangeable Valve Loops - Provide an easy way to reach the

appropriate level of sensitivity for different samples.

Liquid Vaporizer - Unit is equipped with a heated sparger-type

saturator for easy introduction of volatile liquids.

High Temperature Furnace - Temperature up to 1200ºC; with

sub-ambient cooling, the lower limit is -80ºC. Furnace can be linearly

ramped from 1ºC/min to 30ºC/min.

Air Cooling - Cools the furnace rapidly for quick sample turn around.

Sample Temperature - Measured by a moveable thermocouple placed at the

top of the sample bed.

Various Sample Holders - Unit accommodates a variety of quartz U-tubes

sized to accommodate various catalyst volumes and sizes: straight, bubble,

preheat, monolith. Samples may be powders, pellets, extrudates or honeycomb

cores.

Easy Sample Loading - A movable furnace allows easy removing and

loading of the sample holder.

Trap - A trap that may be filled with a desiccant or used as a cold

trap is provided downstream of the sample holder in order to remove

condensables before the TCD.

Heated Null Station - Ensures accurate calibration pulses without

contact with the sample.

Injection

Port - A syringe

injection port is provided for exact loop volume calibration.

Heated Lines - All lines, valves, and parts of the liquid vaporizor

are heated to prevent condensation.

Thermal Conductivity Detector - Highly reliable 4-filament TCD used to

quantify gas uptakes. Excellent linearity, accuracy, sensitivity, and

stability. Several filament options are available.

Direct Mass Spectrometer Link - Ametek's MS data can be integrated in

real-time with AMI-200 data using DDE.

Auxiliary Detectors - Can accept any auxiliary detector providing a

voltage analog output, such as a flame ionization detector (FID).

Low Internal Volume - Low volume valves and 1/16” lines are used

to reduce void volume and minimize peak spreading.

Materials of Construction - Seals and materials are custom engineered

to meet your specifications.

Safety Features - Among others: independent over-temperature protectors

for furnace, resealable pressure relief valves, check valves, circuit

breakers, and fuses. System is designed to fail in safe mode.

|