Product Summary CATALYST CHARACTERIZATION INSTRUMENTS

|

|

|

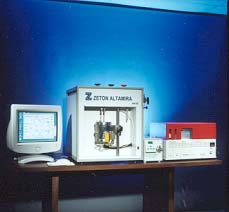

The AMI-200

The AMI-200 combines a variety of temperature-programmed catalyst characterization techniques into one integrated, fully-automated system. Developed for and by catalyst researchers, it offers all the major dynamic techniques for fully characterizing a catalyst. Tests take a fraction of the time required for static methods. |

|

|

The AMI-90

The AMI-90 offers dynamic characterization capabilities in a simple and affordable instrument. The instrument features fully-automated control and data acquisition. Its compact size requires little bench space. The AMI-90 is ideal for the smaller lab, quality control, or for dedicated applications. |

|

|

The AMI-200

IP

The AMI-200 IP is identical to the AMI-200 but adds an Integrated Pretreatment station, so that one sample can be undergoing pretreatment while TPD, TPR/TPO or pulse chemisorption is being performed on another. Then, the pretreated sample gets characterized, in situ, while the other station starts pretreatment of another sample. Operation is still fully automated. Ideal for characterizations with extended pretreatment steps. |

|

|

High

Throughput Characterization

|

|

|

High

Pressure Characterization

The AMI-200HP performs the same TPD, TPR/O, TPRx and pulse chemisorption experiments as the standard AMI-200, but also has the capability to do them at pressures of up to 75 bar (1070 psig). It has a heated gas saturator and heater box to prevent condensation in lines and valves. |

|

|

AMI200

Reactor Systems

The AMI-200 can be also be configured as a reactor system. The AMI-200R, shown at left is equipped with a liquid pump and a vaporizer circuit plus an auxiliary detection stream valve to accept an additional analyzer, such as a GC. The AMI-200R is ideal for reaction studies including fuel cell catalyst research, steam reforming experiments, water-gas shift reactions, auto-thermal reforming, and preferential oxidation experiments. The AMI-200R retains all of the capabilities of the AMI-200 to perform TPR, TPO, TPD, and Pulse Chemisorption experiments |

|

|

High

Pressure Reactor

The AMI-200 can also be configured as a high-pressure reactor system. With one or two liquid pump and vaporizers circuits, the AMI-200R-HP provides a wide range of capability to perform reaction experiments at pressures up to 75 bar (1070 psi), while retaining the capabilities of the AMI-200 to perform Chemisorption experiments |

|

|

|

|

|

High Throughput Screening (HTS) Reactor

Systems

Altamira Instruments supplied HTS reactor systems of its own 10-station design before taking on the Celero product under license from Symyx. They are operating successfully and provide additional validation for prospective Celero buyers. |

|

|

"All-Purpose" Reactor Systems

These reactors share common feed and product collection modules among three or more selectable reactors, e.g., plug-flow fixed bed, CSTR, and Berty reactor. These systems are designed to provide maximum flexibility for a variety of catalytic studies in a single unit. |

|

|

CSTR Systems

Continuous stirred tank reactor (CSTR) systems can be supplied meeting a variety of specifications, including multiple separators for disengaging gases, liquid and waxy products, on-line GC analysis, and automated report generation. They are ideally suited for kinetic studies of slurry-type reactions. |

![]()

|

|

|

SPECIALTY MICROREACTORS

|

|

|

SSITKA Reactor

Steady-State Isotopic Transient Kinetic Analysis (SSITKA) allows mass spectrometric monitoring of reaction transients by performing isotopic switches under steady-state conditions. Kinetic parameters such as active surface intermediates concentration, the ir average residence time, and pseudo-first order reaction constants can be readily determined. |

|

|

Fast-switching Reactor for Auto Emissions

Catalyst Testing

Altamira Instruments can customize or design specialty instruments for your particular application. For example, rapid-aging units that can switch feeds at frequencies up to 2 Hz have been supplied to auto emissions catalyst developers. |

CONSIDER THESE ADVANTAGES OF BUYING FROM

|

149

Phone: 412-963-6385 Fax: 412-963-6485

e-mail: Info@AltamiraInstruments.com